Cleaning Aircraft Spark Plugs - Ignition Service...this is one of the FAA approved tasks that aircraft owners can perform and sign off on their own aircraft.

It's not really a complicated process, but one that deserves careful attention to detail to ensure the job is done right.

Cleaning Aircraft Spark Plugs

This is not a training course...it is just information that will hopefully encourage you as an aircraft owner to get help learning more about spark plugs. Or, if you're already familiar with the process, there might be something new here for you to consider.

Pneumatic Spark Plug Cleaner

Remember to always get training for this type of thing the first time or until you are familiar with doing the task yourself.

At Classic Aviation we stock the barrel with glow plug seals (left). The annealed seals better when the ignition is reinserted. (See the right photo above to see how easy it is to bend a smooth gasket with your fingers.)

Below are a few more things you may want to use to clean spark plugs: Spark plug cleaner explosives and a gap gauge to correct the gap. If you buy a kit like I mentioned above, it may be part of that kit.

One final tip: Keep a spare spark plug or two in your airplane, along with the proper tools to change them if necessary... one day you might be glad you did! Members DO more LEARN more SAVE more - Find out MORE about being a pilot - CLICK HERE

Champion Aerospace Sponsors The A2a Accu Sim C172 Trainer

Your candles work hard in a deadly environment. Choose them wisely to maximize engine performance and reliability.

The average candle is lit 8 million times during a 100 hour flight. It is built to withstand temperatures of 4,000 degrees Fahrenheit, pressures of 2,000 psi and 24,000 volts. Christmas functionality is of course important. You have options, starting with the manufacturer. Both Tempest and Champion make great products. I use Tempest on my plane. Since the beginning, the Tempest has used a very reliable one-piece resistor design, and I love the nickel finish that looks good year after year.

When choosing spark plugs for your engine, approved options can be found in your engine's aircraft and maintenance manuals. The connector part numbers are easy to decode to explain the program in your machine. For example:

For some applications, you will have options regarding the temperature rating of the plugs. A higher temperature means that the tip of the plug gets hotter during use. In an ideal world, the spark plug tip would operate between 1,000 degrees Fahrenheit and 1,200 degrees Fahrenheit, where it is least sensitive to lead, carbon, or oil. It is important to note that these temperatures are not the same as exhaust gas temperatures (EGTs), which we can measure. We are talking about the temperature of the candle core itself. There's no direct way to measure your plug's temperature, so we'll go back and look at the symptoms of any fouling problems you have and choose a different temperature range to adjust accordingly.

Tempest Ureb37e Massive Electrode Aircraft Engine Spark Plug At Skygeek.com

Plugs that are too cold (below 1,000 degrees Fahrenheit) will be vulnerable to cold dirt. Cold impurities appear as precipitates that are light brown (lead) and sooty (carbon). At the other end of the spectrum, plugs that are too hot (above 1,200 degrees Fahrenheit) will appear with a shiny black build-up of lead, carbon or oil deposits.

Your final choice in the design of the plates concerns the electrodes. The most common plug design is the traditional solid electrode plug. However, projected core plugs that look like car plugs are also available that can help reduce lead problems. Switching to high-quality, fine-wire plugs reduces contamination, improves engine starting/smoothness, and extends the life of the pads by three to four times. Fine thread plugs are an excellent choice for high performance machines.

Spark plug maintenance involves simple cleaning and rotation on an annual or 100-hour schedule. Cleaning should be done carefully with a hand pick or vibrating cleaner to remove lead deposits and Hoppe's No. 9 laser. Bead blast cleaner should only be used on large plugs and should be used very sparingly. Never use glass sand or silica in a plug-in bead blower, and never use a grinder with a wire brush. Both of these can lead to contamination that can cause a conductive short that destroys the plug. If you must use a blaster, use crushed walnuts or "Black Diamond" medium from Aircraft Tool Supply.

One final check should be to verify that the resistance of the plugs is below 5,000 Ohms. When the plug's resistance gets higher than this, it's time for a new plug. And remember the old Christmas saying: "Throw it once, drop it twice" (the second drop is in the trash). Once a plug has fallen to the floor, there is no way to tell if the ceramic has been compromised. You just need to change the plug.

Tips From Mechanics To Keep Your Airplane In Great Shape

Plugs must be rotated when reinserted. This evens out the electrode wear so that the plug center electrode and side electrodes wear evenly and extend the life of the plug.

Finally, always install the plugs with new gaskets and a light coating of non-conductive anti-seize, avoiding covering the first two to three wires. This ensures that anti-seize agents do not enter the combustion chamber.

Proper ignition maintenance can greatly improve the reliability of the ignition system. However, it's important to remember that one of your most powerful tools for keeping your plugs healthy on every flight is in your hand: the mix control. Lean on the ground to prevent frostbite and follow the aircraft manufacturer's recommendations for in-flight lean. You save money on both maintenance and fuel in the process. Until next time...Happy Flying!

Jeff Simon is an A&P mechanic, IA, pilot and aircraft owner. He has spent the past 22 years promoting owner-assisted aircraft maintenance and created the first alternator clutch inspection tool available on ApproachAviation.com. Jeff is also the creator of SocialFlight, the free mobile app and website that maps over 20,000 aviation events, hundred dollar civilian destinations and also offers educational aviation videos. Free apps are available for iOS and Android devices, and users can also visit www.SocialFlight.com.

Buy Sunex 3912 Spark Plug Cleaner Online At Lowest Price In Ubuy India. B002rvrkjo

Aircraft Spruce provides just about everything a pilot or aircraft owner could need. As a strategic partner since 2012, the company has sponsored programs that bring knowledge and DIY spirit to members. Members DO more LEARN more SAVE more - Find out MORE about being a pilot - CLICK HERE

We all know what aircraft spark plugs do: They receive high-voltage pulses from a solenoid or electronic ignition unit and produce an electric spark inside the cylinder's combustion chamber to ignite the air/fuel mixture and start a flame. They do this approximately 20 times per second in hostile conditions of extreme heat and pressure.

Plugs should be gone when either the center electrode or the ground electrode reaches half its original size.

A spark plug has three coaxial parts: a center electrode, a ceramic insulator and a steel barrel. The barrel is threaded on both ends; one end screws into the cylinder head and the other end fits the ignition cable. The insulator is made of aluminum oxide ceramic to provide good strength, thermal conductivity and electrical properties. The center anode comes in two flavors: solid and fine wire.

How To Install Aircraft Sparkplugs

When a spark jumps the gap between the center electrode of the spark plug and the ground electrode, one electrode loses a trace amount of metal due to ionization. This happens 75,000 times an hour and this loss of electrode metal gradually widens the gap and eventually wears out the electrode rendering the clone unusable.

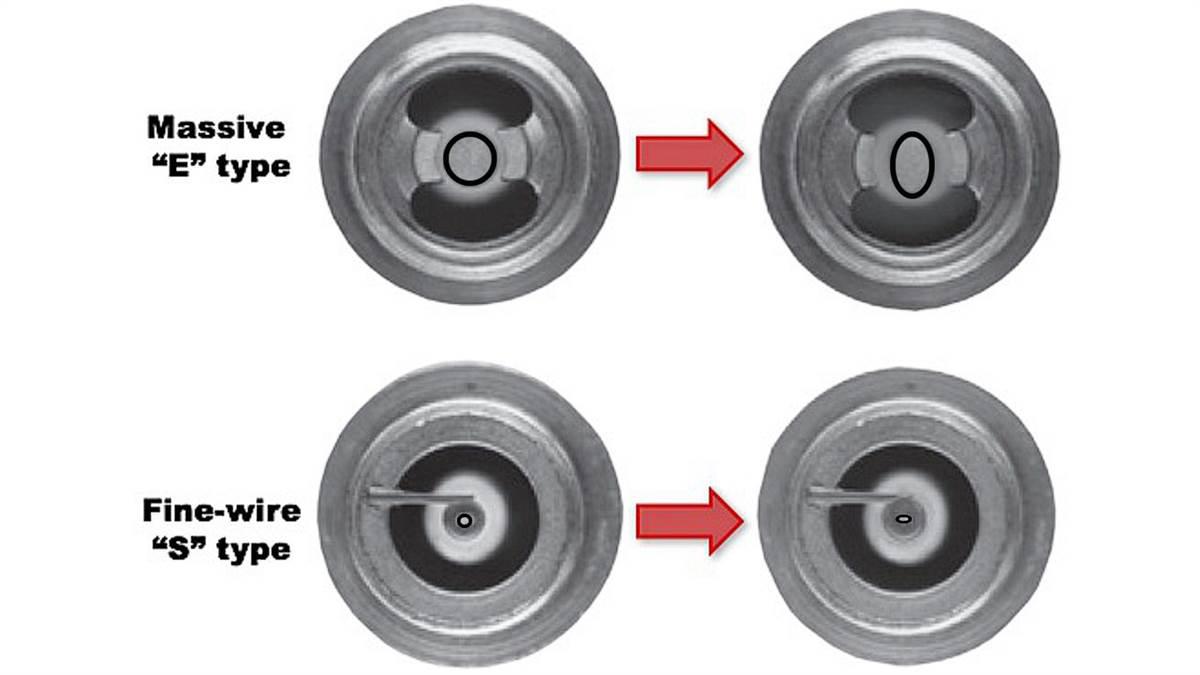

Central anodes begin with a circular diameter and gradually become football-shaped in use due to erosion. When the short dimension reaches half the long dimension, it is time to stop cramming. Likewise, when ground electrodes wear down to half their original size, the plug should be removed.

Magnetos generate high voltage pulses with alternating polarity. When a candle is lit with a negative pulse, metal is lost from the center electrode; when fired with a positive pulse, metal is lost from the anode(s). In a horizontal resistance engine with an equal number of cylinders, half of the plugs in the engine are shorted at the center electrode, while the other half are shorted at the ground electrode(s). By regularly rotating the plugs to the opposite polarity, you can even out the wear of the electrodes and extend the life of the plugs.

Normally, spark plugs are removed every 100 hours for cleaning, cleaning and rotation. However, I prefer to do periodic in-flight ignition checks and perform spark plug maintenance only when those checks show less than stellar ignition performance; I find this approach to conditioning leads to less maintenance.

Tempest Urhm38e Massive Electrode Aircraft Engine Spark Plug At Skygeek.com

When it's time to do preventative maintenance, I remove the spark plugs and put them in a spark plug tray so I don't forget which spark plug came from which position in which cylinder. So me

Aircraft spark plugs for sale, champion aircraft spark plugs, cleaning fouled spark plugs, champion aircraft spark plugs application chart, cleaning spark plugs with wd40, tempest aircraft spark plugs, spark plugs cleaning, cleaning iridium spark plugs, cleaning spark plugs with torch, aircraft spark plugs cross reference, cleaning spark plugs vs replacing, aircraft spark plugs

0 Comments